Stable packing

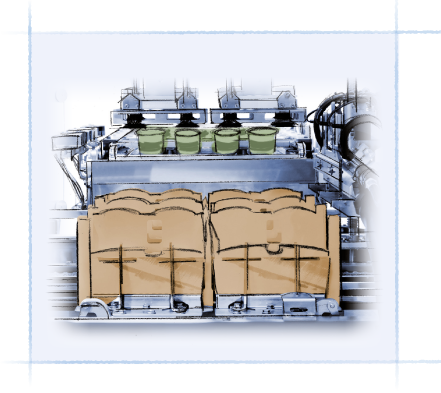

Sleeve Wrapper

Stable packaging of primary-packed products – sema Carton Sleevers.

sema Carton Sleevers are multi-functional, compact systems for re-packaging primary packaged products in cardboard sleeves (clusters), trays or crates. Its finely tuned modular design guarantees an output of up to 50,000 cups per hour.

sema Carton Sleevers have been systematically designed for wet operation. Their open constructions, lack of hollow sections in sensitive areas and the use of laser sheet metal structural parts result in user-friendly, long-lasting systems. Take advantage of the design of the clusters, which is optimised to meet marketing requirements. And leave it up to the extremely durable carton sleevers.

sema Carton Sleever at a glance

sema Carton Sleevers 6000 i

For packaging primary-packed products and for producing multipacks (clusters) from flat blanks.sema Carton Sleevers 6000 i

Highlights

- Speed: up to 50,000 primary packaged products per hour

- Processing of full sleeves, head sleeves, drop-in sleeves and partial sleeves

- Integrated series for fitting to cup filling and sealing machines, cup forming, filling and sealing machines and bottle filling and sealing machines

- Avoidance of interfaces thanks to integrated overall concept (cup packer, cup transporter, sleeve wrapper, package transport and packer in one machine)

- Usage of maintenance-free sema two-axle robot with formatflexible gripping/picking system, User-friendly due to low magazine loading height

Sleeve Wrapper 6100 s

For packaging primary-packed products and for producing multipacks (clusters) from flat blanks.Sleeve Wrapper 6100 s

Highlights

- Packaging of FS cups, FFS cups and bottles

- Output: up to 30,000 primary-packed products per hour

- Processing of full sleeves, head sleeves, drop-in sleeves and partial sleeves

- Stand-alone series for integration into packaging lines

- Avoidance of interfaces through an integrated overall concept: carton sleeving, pack transport and case packing in one machine

- Product feed system with gentle product handling

- Usage of maintenance-free sema two-axle robot with formatflexible gripping/picking system, User-friendly due to low magazine loading height

- User-friendly due to low magazine loading height