Straightness measurement

X-Line – Laser measuring system for straightness testing of rods and pipes

Improved product quality through straightness measurement

With our innovative laser technology, you can check the straightness of a round profile inline and with a single measuring routine.

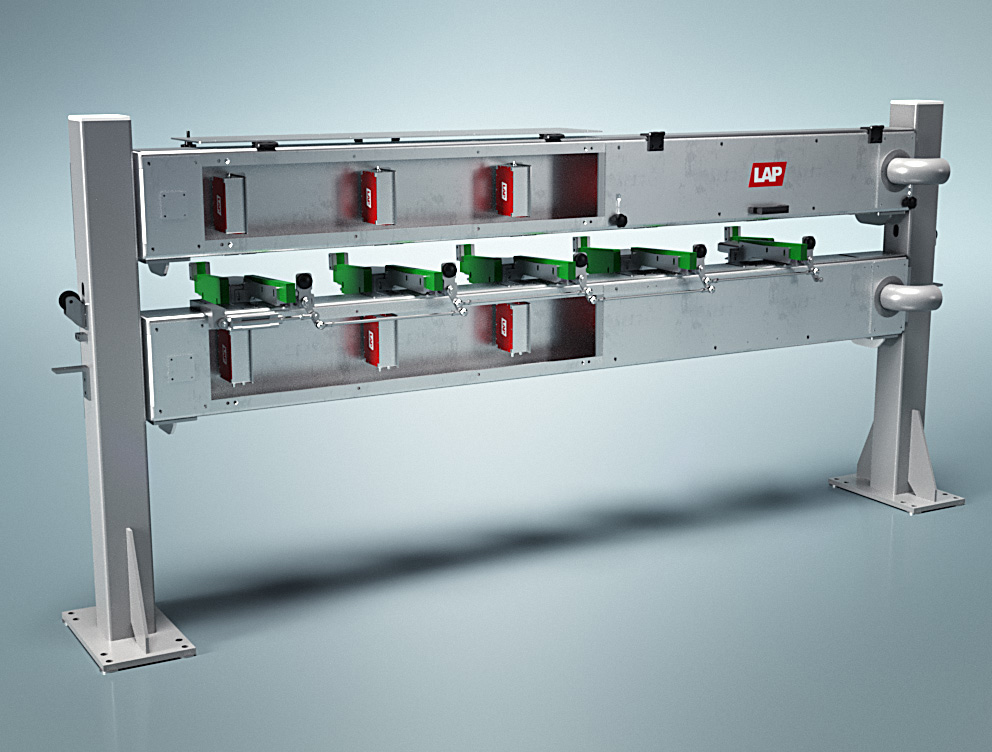

The measuring frame is installed directly in the line and contains at least three LAP measuring sensors.

The object rolls individually through the measuring system during the inspection process and is scanned.

The measurement result shows the deviation of straightness in millimetres in relation to a reference length of one meter.

Optionally, you can determine other measured variables such as the length and ovality of the object.

Together for your success

This process is unique on the market and was developed with our partner LAP GmbH Laser Applications developed.

You receive verifiable quality assurance of your rods or tubes during ongoing production.

The modular design allows individual configuration and can be easily integrated into the existing system.

Benefit from the expertise and experience of two strong partners.

Features of the Straightness Check X-Line

FLEXIBLE PRODUCT SIZE

Thanks to the controlled material guidance throughout the production process, rods and tubes of different sizes and lengths can also be tested without any problems

CONTACT-FREE MEASUREMENT

With our optical method, you can measure straightness without contact and avoid any mechanical wear on the measuring system or the product.

MATERIAL INDEPENDENT

The Straightness Check X-Line measures independently of physical or chemical material properties, color or reflectance.

The measuring system can therefore be used flexibly.

X-Line Software

The intuitive software reads in the measured values and calculates the straightness and diameter during the process.

The measurement results are evaluated based on the product specifications and tolerance violations are signaled via digital outputs.

The software displays the deviation in straightness in real time and gives an early alarm if the tolerance is exceeded.