Packaging Technology

Tray Former

For efficient operation:

folding and gluing trays and crates

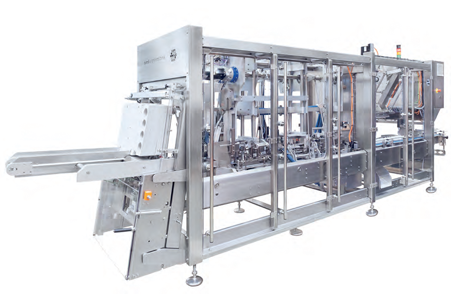

For the production of open trays and crates, we offer the sema tray former in two high-quality series, beginning with the single-format basic machine up to the multi-format high-speed machine with an output of up to 80 trays per minute.

An open construction with overhead drives make the sema tray and carton former easy to operate at all times. The sema drive design stands out for its trouble-free operation and efficiency. We have therefore also reduced the servo-drives to the minimum necessary, without increasing the number of pneumatic drives. This saves energy, protects materials and reduces your expenses. This saves energy, is gentle on materials and reduces your costs.

Overview of sema tray formers

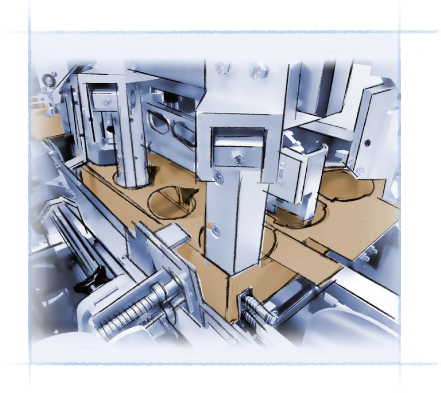

Tray Former 1100 s

For the production of open trays from flat blanks.Tray Former 1100 s

Highlights

- Speed of up to 50 trays per minute

- Open construction in stainless steel design

- Processing of solid board and corrugated board

- Available as a single-format or format-flexible system with short changeover times and no change parts required

- Operator-friendly and easily accessible thanks to a movable forming magazine

- Use of high quality construction elements

- Verarbeitung von Sonderfaltungen z. B. Inside/Outverklebung

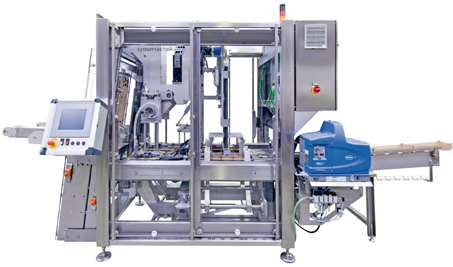

Carton erector 1200 s

For the production of perforated trays from flat blanks.Carton erector 1200 s

Highlights

- Power up to 60 rises/min

- Available as a format-flexible system with short changeover times

- Open construction in stainless steel design

- Optimised use of servo technology thanks to group drive design

- Operator-friendly and easily accessible thanks to top-mounted drives

and large transparent panel guarding - Integratable add-on modules for divisible trays, trays with display panels, and double-glued trays

Tray-Former 1300 s with integrated Top-Loader

Compact design – fast in operation: efficient packaging of cups and bucketsTray-Former 1300 s with integrated Top-Loader

Highlights

- Package formats 1 x 3 x 1 and 1 x 3 x 2

- 7,200 1-kg buckets/hour

- 1,500 trays/hour

- Format flexibility at tray and product dimensions due to interchangeable parts and settings

- Open design, stainless steel version

- Packaging of jars, bottles and cups in open trays

- Formatflexible in tray-forming and product handling

- Modular product infeed systems for outputs of up to 35 cartons per minute

Tray Former 1400 s

For the production of perforated trays from flat blanks and for packaging cups, jars, etc. into the traysTray Former 1400 s

Highlights

- Formatflexible in tray-forming and product handling

- Short change over times due to formatfl exible gripping/picking system and a small number of change parts

- Product specific construction of feeding and grouping systems

- Optimised use of servo technology thanks to group drive design

- Operator-friendly and easily accessible thanks to top-mounted drives and large transparent panel guarding

- Open construction in stainless steel