Inspecting

Careful inspection

Non-destructive testing of bars and tubes –

your partner sema

-

Various testing tables for e.g. ultrasonic, eddy current, magnetic inductive and leakage flux testing (in close cooperation with renowned manufacturers)

- Optionally equipped with belt drivers, prism roller drivers or triple centring drives

- Fully automated testing lines

- Feeding systems for testing units with separation units and sorting bins

- Integration of systems for length, diameter and straightness testing, as well as paint marking

sema driver and testing tables at a glance

Straightness measurement

X-Line – Laser measuring system for straightness testing of rods and pipesStraightness measurement

Improved product quality through straightness measurement

- Innovative laser technology for inline straightness inspection of round profiles

- Measuring frame can be integrated directly into the production line

- Scanning of the object for precise measurement

- Millimetre-accurate measurement results

- Optional determination of additional measurement parameters

Test lines

Non-destructive testing with defect sortingTest lines

Highlights

- Maximum guiding precision

- Fully automatic separation and feeding

- Testing possible without a gap (e.g. ultrasound for pipes)

- Precise marking of the tested fault locations

- Multiple sorting depending on the test error

- Interlinking with sawing systems to cut off imperfections or untested ends

- Integration of geometry checks such as length, diameter, straightness, etc.

- Kundenspezifische Auslegung des Materialhandling

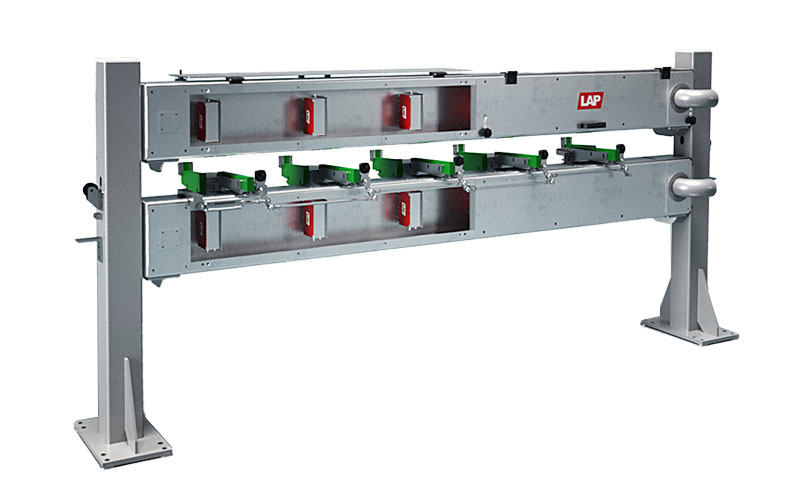

Testing unit

Non-destructive testing at speeds of up to 240 m/minTesting unit

Highlights

- Large diameter range

- Highly precise measuring systems for height and diameter adjustment

- Automatic format changeover

- Stable, precise basic design

- Modular design

- Proven interface to all major testing equipment manufacturers