Straightening

Neat straightening

Tubes and profiles with maximum straightness and precision – thanks to sema straightening machines.

We manufacture

- Six- and ten-roll straightening machines for tubes and profiles

- Two-roll straightening machines for bar steel, as well as horizontal and vertical straightening units – also for copper, brass and aluminium

High structural rigidity, the consistent use of servo motors and state-of-the-art control technology: sema straightening machines ensure perfect straightness, roundness and surface quality – with excellent ease of operation.

sema straightening machines at a glance

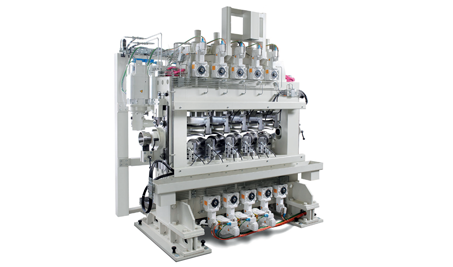

10-roll straightener

Precise straightening of round tubes10-roll straightener

Highlights

- Large diameter range

- Automatic presetting of the straightener

- Asymmetrical straightening roller shape

- Highly precise measuring systems for angle and diameter adjustment

- Individual servo drives for the straightening rolls

- Maximum setup time: 10 minutes with one operator

- Electronic handwheel

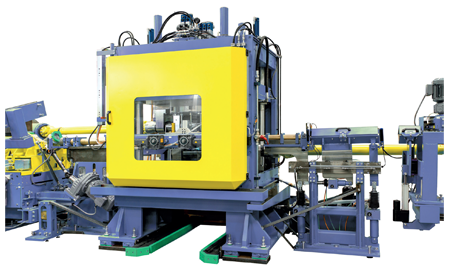

2-roll straightening and polishing machine

Precise straightening of peeled or drawn round bars2-roll straightening and polishing machine

Highlights

- Hydraulic roller quick-change system

- Maximum changeover time: 15 minutes.

- Motorised guide ruler

- 4-column guide system, torsion-resistant,

with height adjustment via screw-lift elements.