Saws

Cut better. Perform better.

sema sawing systems: Robust design and high cutting quality with short cycle times.

Sawing systems for tubes and bars are available in various versions:

- Cut-to-length sawing systems with multiple automatically movable sawing stations

- Fixed-length sawing systems

- Layer sawing systems

- Precision length sawing systems

- Sawing and brushing systems for cutting and deburring bar and tube material

sema saws at a glance

Underfloor multi-saw

Synchronous cutting of bars and tubesUnderfloor multi-saw

Highlights

- Precise saw cuts with high availability

- High availability

- Excellent accessibility thanks to service-friendly design

- Horizontal centric clamping with multi-range prism jaws

- Shortest non-productive times thanks to sawing from bottom to top

- Cut-optimized saw blade feed

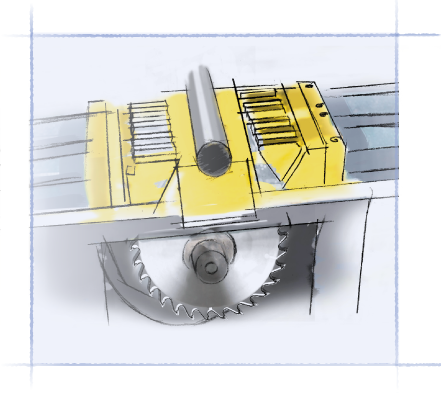

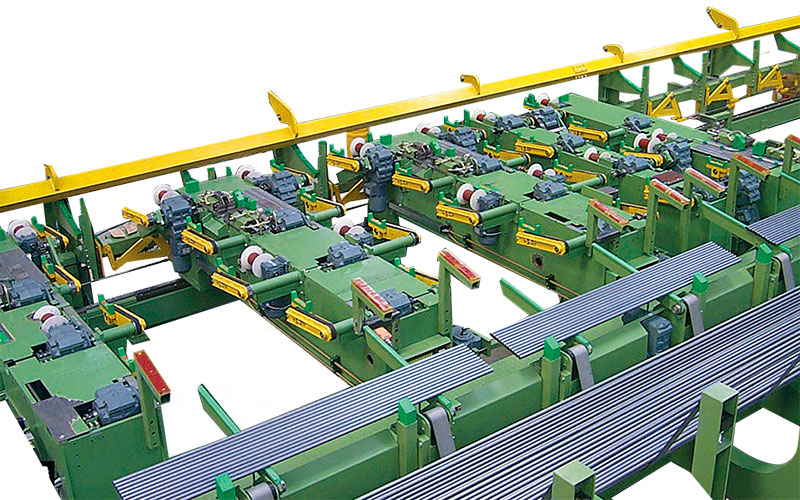

Above-floor multi-saw

Precise cutting of round tubesAbove-floor multi-saw

Highlights

- Shortest cycle times with maximum flexibility

- Very wide speed range for HSS and carbide blades

- Individual sawing routines with optimized cutting

- Storing of sawing order data in recipes

- Fully automatic format changeover

- Simultaneous cutting of fixed and random lengths

- Automatic cutting and discharge of samples as well as automatic length sorting

- Integrated brush deburring or chamfering unit

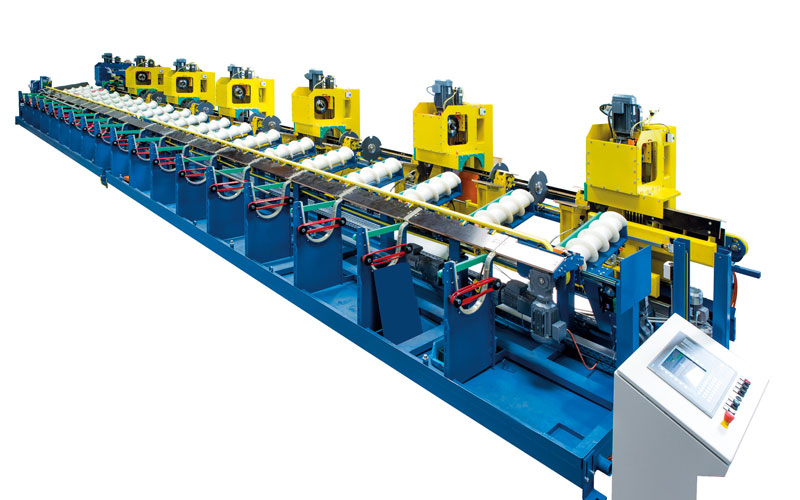

High-performance sawing systems

Precise and cost-efficient cuttingHigh-performance sawing systems

Highlights

- Use of carbide and HSS saw blades

- Saw feed by via preloaded ball screw drive

- Double-sided saw blade guidance

- Robust, precise and fast

- Hydraulic kerf widening system

- Optimized chip removal